CAI: Accelerating your digital strategies ahead

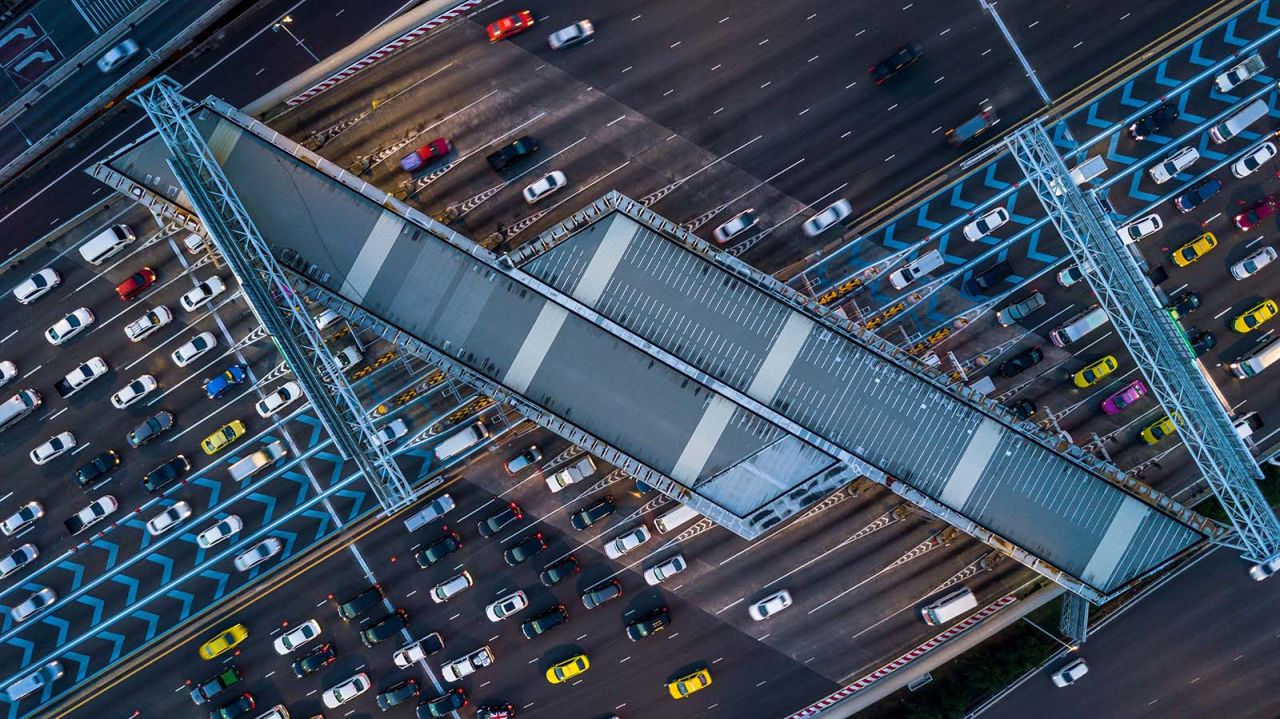

A southern state’s turnpike agency is one of the largest toll enterprises in the U.S., operating 600 miles of road and generating more than $1 billion a year. In its efforts to streamline operations and increase safety for its constituents, the agency made a name for itself in the public sector as one that embraces leading-edge business and technical solutions.

In 2005, the agency became one of the first tolling agencies in the U.S. to enable technicians to monitor, detect and diagnose problems in its toll collection systems remotely with the opening of an operations center—a command-and-control technical support center designed to manage toll collection systems around the clock, 24 hours a day, seven days a week. The operations center’s computers track equipment, systems, software, and facilities, depicting the data with maps and status charts on high-tech wall-size monitors, and allowing staff to keep their fingers on the pulse of the system’s performance across the state. In the case of a malfunction, center staff can restart toll collection devices or initiate a repair from a remote workstation often without dispatching a technician.

Though the center enabled 24x7 monitoring, the agency knew it could operate even more effectively if it moved from reactive to proactive maintenance. To do so, the agency turned to CAI, which had been providing its technical and operations, and maintenance support for a decade, to help create a team of multi-disciplinary experts in network communications, toll equipment operations and maintenance, finance, and back-office processes to solve the problem of revenue leakage from suboptimal equipment and systems. While traditional monitoring teams are focused on detecting and fixing hardware or system failures, this Supplemental Lane Analysis and monitoring (SLAM) team were to focus on more subtle degradation of equipment and systems that might otherwise go undetected.

The SLAM team defined a set of performance metrics available from transaction and back-office data, then set up a means to collect, summarize and monitor it via reports and dashboards. If members of the SLAM team identify a hard failure not previously detected by the operations center, they forward it to front-line maintenance teams for immediate resolution. The team then focuses the majority of its time on more subtle design-level issues or performance improvement opportunities. The SLAM team logs and investigates these issues over time with assistance from outside parties, such as lane vendors and software architects.

Proactive daily analytics and root cause analysis enabled the team to detect and repair degraded equipment before failure, modify lane systems to improve data capture, and implement video toll processing improvements. In its first three years of operation, the SLAM team logged and closed 250 investigative items, including 12 complex issues that resulted in system upgrades, increased revenue collection, and operational efficiencies that generated $30 million.